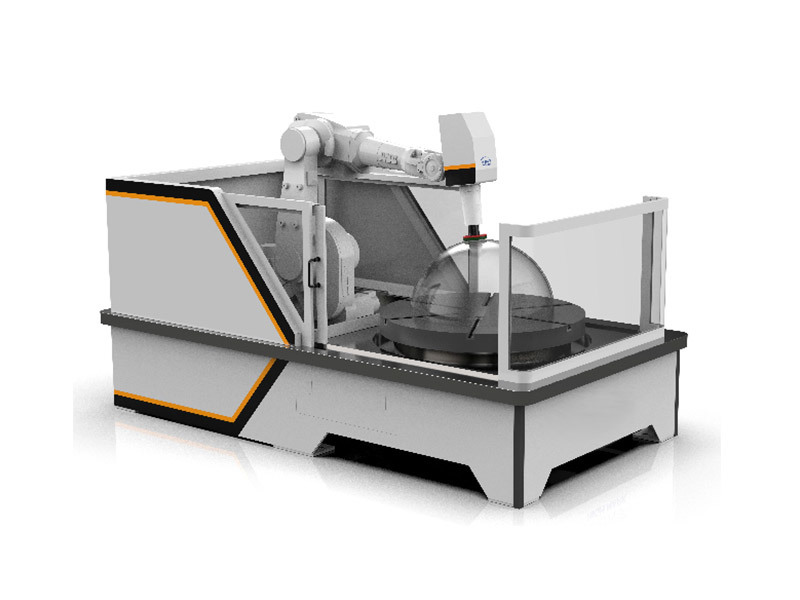

Multi-Function Desktop Robot Polisher

Keywords:

Multi-Function Desktop Robot Polisher

Category:

- Details

- Characteristics

- Parameters

- Application

-

- Commodity name: Multi-Function Desktop Robot Polisher

The Computer Control Optic Surfacing Polisher Basing on mini industrial robot,with less space and more flexibility. The surface error is figured by the polishing spindle tool, using for optical plane, spherical and aspheric surface. The fitting polishing tool technology basing on the polishing force controller was developed to get the controllable Influence Function and finish the precision optical surface. And High Mark will provide full process solutions from micron to nanometre with the innovative process technology and software.

The Computer Control Optic Surfacing Polisher Basing on mini industrial robot,with less space and more flexibility. The surface error is figured by the polishing spindle tool, using for optical plane, spherical and aspheric surface.

The fitting polishing tool technology basing on the polishing force controller was developed to get the controllable Influence Function and finish the precision optical surface. And High Mark will provide full process solutions from micron to nanometre with the innovative process technology and software. -

1.The innovative control system for polishing robot, to get ultra-precision optic surface.

2.The special polishing tool with force control for precision Influence Function.

3.The process software for customization.

4.The attachment device for customization. -

Projection Parameters Materials of processing Fused silica, K9, Zerodur, Alloy aluminium Aperture ≤500mm Spindle speed 0-3000rpm repeat position accuracy 0.02mm Shaft accuracy 0.01mm Side face accuracy 0.01mm Diameter of rotate table 500mm Rotation accuracy of rotate table 0.001 degrees